|

|

We at Hitech Instrumentations and supply technically advanced, High Quality Valves for critical services in Oil, Gas, Petro-Chemicals, Fertilizers, Power Generation and many other Industrial Applications. |

|

| Ball Valves | ||

|

Ball Valves are mostly widely used in Control Panels, Instruments and Process Plants, Laboratories and Power Plants. The main advantages of Ball Valves are ... |

||

|

|

|

|

|

Ball Valve 1 |

Ball Valve 2 |

Ball Valve 3 |

|

|

||

| Ball Valve 4 | ||

| Needle Valves | ||

|

Needle Valves have been designed to give higher strength and integrity to instrument needle valves. UI have incorporated a dynamic multi-ring gland system in the needle valve, which when combined with the anti blow-out back seating stem, guarantees resistance to all operating Processes and pressures. Low operating torques and high cycle life feature strongly in this unique UI design, giving a "Low Cost of Ownership". Key Benefits are:

|

||

|

|

|

| Needle Valve 1 | Needle Valve 2 | Needle Valve 3 |

|

|

|

| Needle Valve 4 | Needle Valve 5 | Needle Valve 6 |

|

|

|

|

Needle Valve 7 |

Needle Valve 8 |

Needle Valve 9 |

|

|

|

|

|

Needle Valve 10 |

Needle Valve 11 |

|

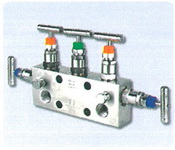

| Mainfold Valves | ||

|

Manifold Valves are mainly used in gauge and static instrument applications such as Pressure switches, Pressure Transmitters and Manometers. The Manifold will isolate instrumentation from the process and allow venting of instrument from calibration, removal from the circuit without affecting the process/application and or recovery of sample. |

||

|

|

|

|

|

Manifold Valves 1 |

Manifold Valves 2 |

Manifold Valves 3 |

|

|

|

|

|

Manifold Valves 4 |

Manifold Valves 5 |

Manifold Valves 6 |

|

|

|

|

|

Manifold Valves 7 |

Manifold Valves 8 |

Manifold Valves 9 |

|

|

|

|

|

Manifold Valves 10 |

Manifold Valves 11 |

Manifold Valves 12 |

|

|

|

|

|

Manifold Valves 13 |

Manifold Valves 14 |

Manifold Valves 15 |

| Check Valves | ||

|

Check Valves or Non Return Valves as called are used in all types of Gas or Liquid Service where unidirectional flow is required. |

||

|

|

|

|

|

Non Return Valve 1 |

Non Return Valve 2 |

Non Return Valve 3 |

HOME : PROFILE : PRODUCT RANGE : APPLICATIONS : QUALITY ASSURANCE : CONTACT US : CLIENTS